PRODUCTS

- Distribution Transformer

- Resin Casting Dry Type Power Transformer

- Whole-sealed Type Distribution Power Transformer

- Electrical Power Fitting

- Power Transmission and Distribution Fittings

- Power Line Fittings

- Power Line Helical Fittings

- High Voltage Outdoor Electrical Equipment

- Copper and Aluminum Contact Arms

- Lightening Protection Grounding Clamps

- Electric Wire & Cable and Accessories

- Rubber Sheathed Cable for General Purposes

- Rubber Insulated Cables Used in Open Countr

- Flame-retardant Rubber Sheathed Cables for Mining Purposes

- PVC Insulated Cable for House Wiring

- XLPE Insulated Power Cable

- PVC Insulated Power Cable

- Low-smoke Halogen-free Flame-retardant and Fire-resistant Cables

- Control Cables

- Overhead Conductors and Cables

- Aluminum wire and ACSR

- Special Cables

- Elevator Cable

HOTLINE

0577-57157777

Flame-retardant Rubber Sheathed Cables for Mining Purposes

Flexible Rubber Sheathed Coal Cutter Cables for Rated Voltage up to 1.9/3.3kV

- Share:

1. Application

This product is used as power supply connection cable for coal cutters or similar equipment of rated voltage 1.9/3.3kV and below.

The max. conductor temperature of 0.38/0.66kV cable in normal use is 90℃ and the sheath is black.

The max. conductor temperature of 0.66/1.14kV cable in normal use is 90℃ and the sheath is yellow.

The max. conductor temperature of 1.9/3.3kV cable in normal use is 90℃ and the sheath is black.

The min. bend diameter of the cables is 6 times cable diameter and the cable with yellow sheath can not be exposed to sunlight for a long time.

3. Code, Description and Usage

| Code | Description | Usage |

| MC-0.38/0.66 | 0.38/0.66 kV rubber sheathed flexible coal cutter cable | Power supply connection cable for coal cutters and similar equipment of rated voltage 0.38/0.66 kV |

| MCP-0.38/0.66 | 0.38/0.66 kV rubber sheathed flexible coal cutter cable with screen | Power supply connection cable for coal cutters and similar equipment of rated voltage 0.38/0.66 kV |

| MCP-0.66/1.14 | 0.66/1.14 kV rubber sheathed flexible coal cutter cable with screen | Power supply connection cable for coal cutters and similar equipment of rated voltage 0.66/1.14 kV |

| MCP-1.9/3.3 | 1.9/3.3 kV rubber sheathed flexible coal cutter cable with screen | Power supply connection cable for coal cutters and similar equipment of rated voltage 1.9/3.3 kV |

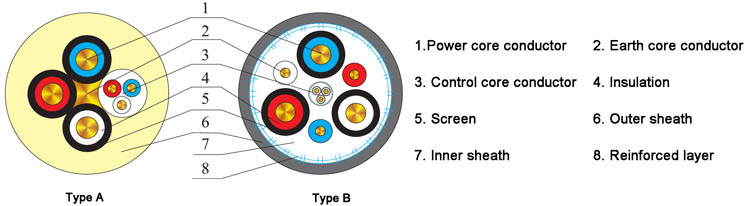

4. Sectional Drawing

5. Technical Particulars

1) MC-0.38/0.66, MCP-0.38/0.66

|

No. of Cores * Sectional Area (mm2) |

Power Core Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) | ||||

| MC-0.38/0.66 | MCP-0.38/0.66 | ||||||

| Power Core | Earth Core | Min. | Max. | Min. | Max. | ||

| 3*6 | 1*4 | 1.6 | 4.5 | 29.1 | 34.1 | 33 | 38 |

| 3*25 | 1*6 | 1.8 | 5.5 | 36 | 41 | 39 | 45 |

| 3*35 | 1*6 | 1.8 | 5.5 | 39 | 45 | 42.5 | 48.5 |

| 3*50 | 1*10 | 2.0 | 5.5 | 44 | 50.5 | 47.5 | 54.5 |

| 3*70 | 1*16 | 2.2 | 6.0 | 50 | 57.5 | 53 | 60.5 |

| 3*95 | 1*25 | 2.2 | 6.0 | 56 | 63.1 | 59.5 | 67 |

| 3*120 | 1*35 | 2.4 | 6.0 | 60.5 | 68.5 | 63.5 | 72 |

2) MCP-0.66/1.14

| No. of Cores * Sectional Area (mm2) |

Power Core Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) | ||||||

| MCP-0.66/1.44 | |||||||||

| Power Core |

Earth Core (Type A) |

Earth Core (Type B) |

Type A | Type B | |||||

| Type A | Type B | Min. | Max. | Min. | Max. | ||||

| 3*25 | 1*6 | 2.0 | 6 | 29.1 | 34.1 | 33 | 38 | ||

| 3*35 | 1*6 | 3*10/3 | 2.0 | 6 | 7 | 36 | 41 | 39 | 45 |

| 3*50 | 1*10 | 3*16/3 | 2.0 | 6 | 7.5 | 39 | 45 | 42.5 | 48.5 |

| 3*70 | 1*16 | 3*25/3 | 2.2 | 7 | 7.5 | 44 | 50.5 | 47.5 | 54.5 |

| 3*95 | 1*25 | 3*25/3 | 2.4 | 7 | 7.5 | 50 | 57.5 | 53 | 60.5 |

| 3*120 | 1*35 | 3*35/3 | 2.6 | 7 | 7.5 | 56 | 63.1 | 59.5 | 67 |

| 3*150 | 1*35 | 3*50/3 | 2.6 | 7 | 7.5 | 60.5 | 68.5 | 63.5 | 72 |

3) MCP-1.9/3.3

| No. of Cores * Sectional Area (mm2) |

Power Core Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) | ||||||

| MCP-1.9/3.3 | |||||||||

| Power Core |

Earth Core (Type A) |

Earth Core (Type B) |

Type A | Type B | |||||

| Type A | Type B | Min. | Max. | Min. | Max. | ||||

| 3*25 | 1*6 | 2.8 | 6 | 44.5 | 51.0 | ||||

| 3*35 | 1*6 | 3*10/3 | 2.8 | 6 | 7 | 48.0 | 54.5 | 59 | 64 |

| 3*50 | 1*10 | 3*16/3 | 2.8 | 6 | 7.5 | 54.0 | 61.5 | 63 | 69 |

| 3*70 | 1*16 | 3*25/3 | 3.0 | 7 | 7.5 | 60.0 | 67.0 | 68 | 775 |

| 3*95 | 1*25 | 3*25/3 | 3.0 | 7 | 7.5 | 65.0 | 72.5 | 69 | 78 |

| 3*120 | 1*35 | 3*35/3 | 3.2 | 7 | 7.5 | 69.5 | 77.5 | 74 | 84.5 |

| 3*150 | 1*35 | 3*50/3 | 3.2 | 7 | 7.5 | 74.0 | 82.5 | 78.5 | 88 |

6. Technical Performance

1) The conductor resistance shall meet the following requirements

| Power Core Sectional Area (mm2) | Max. conductor DC resistance at 20℃ (Ω/kM) | Power Core Sectional Area (mm2) | Max. conductor DC resistance at 20℃ (Ω/kM) |

| 4 | ≥5.09 | 35 | ≥0.565 |

| 6 | ≥3.39 | 50 | ≥0.393 |

| 10 | ≥1.95 | 70 | ≥0.277 |

| 16 | ≥1.24 | 95 | ≥0.210 |

| 25 | ≥0.795 | 120 | ≥0.164 |

2) The insulation resistance meets the following requirements

| Cores |

Nominal Sectional Area (mm2) |

Insulation Resistance at 20℃ (MΩ·kM) | |

| 0.66/1.14kV and below | 1.9/3.3kV and below | ||

| Power Core | 16 | ≥350 |

|

| 25 | ≥300 | ≥450 | |

| 35 | ≥250 | ≥400 | |

| 50 | ≥250 | ≥350 | |

| 70 | ≥200 | ≥300 | |

| 95 | ≥200 | ≥250 | |

| 120 | ≥200 | ≥250 | |

| 150 | ≥180 | ≥250 | |

| Earth Core | 2.5/4/6/10 | ≥100 | ≥100 |

3) Max. conductor temperature in normal use: 90℃.

4) Insulation tensile strength is over 6.5MPa, and has an elongation of over 200% at break.

5) Sheath tensile strength is over 11.0MPa, and has an elongation of over 250% at break.

6) 0.38/0.66kV cables can withstand a 3.0kV/5Min voltage test and no breakdown shall occur; 0.66/1.14kV cables can withstand a 3.7kV/5Min voltage test and no breakdown shall occur; 1.9/3.3kV cables can withstand a 6.8kV/5Min voltage test and no breakdown shall occur.

7) The flame-retardant performance of the cable meets all requirements of burn test in standard MT 386-1995.

-

0.66/1.14kV Screened Coal Cutter Cable with Reinforced Layer and Monitoring Core

-

Flexible Coal Cutter Cables with Individual Metallic Screens of Rated Voltage up to 1.9/3.3kV

-

Flexible Frequency Converter Cable for Coalcutter of Rated Voltage 8.7/10kV and below

-

Flexible Rubber-sheathed Portable Mining Cables for Rated Voltage up to 0.66/1.14kV

-

Rubber Sheathed Flexible Cable with Metallic Screen and Monitoring Core of Rated Voltage 8.7/10kV and below

-

Rubber-sheathed Flexible Portable Cables of Rated Voltage up to 6/10kV

-

Drill Cable for Mining Use of Rated Voltage 0.3/0.5KV

-

0.3/0.5kV Light-duty Flexible Portable Cable for Mining Use

-

0.6/1kV PVC Insulated Power Cable for Mining Use